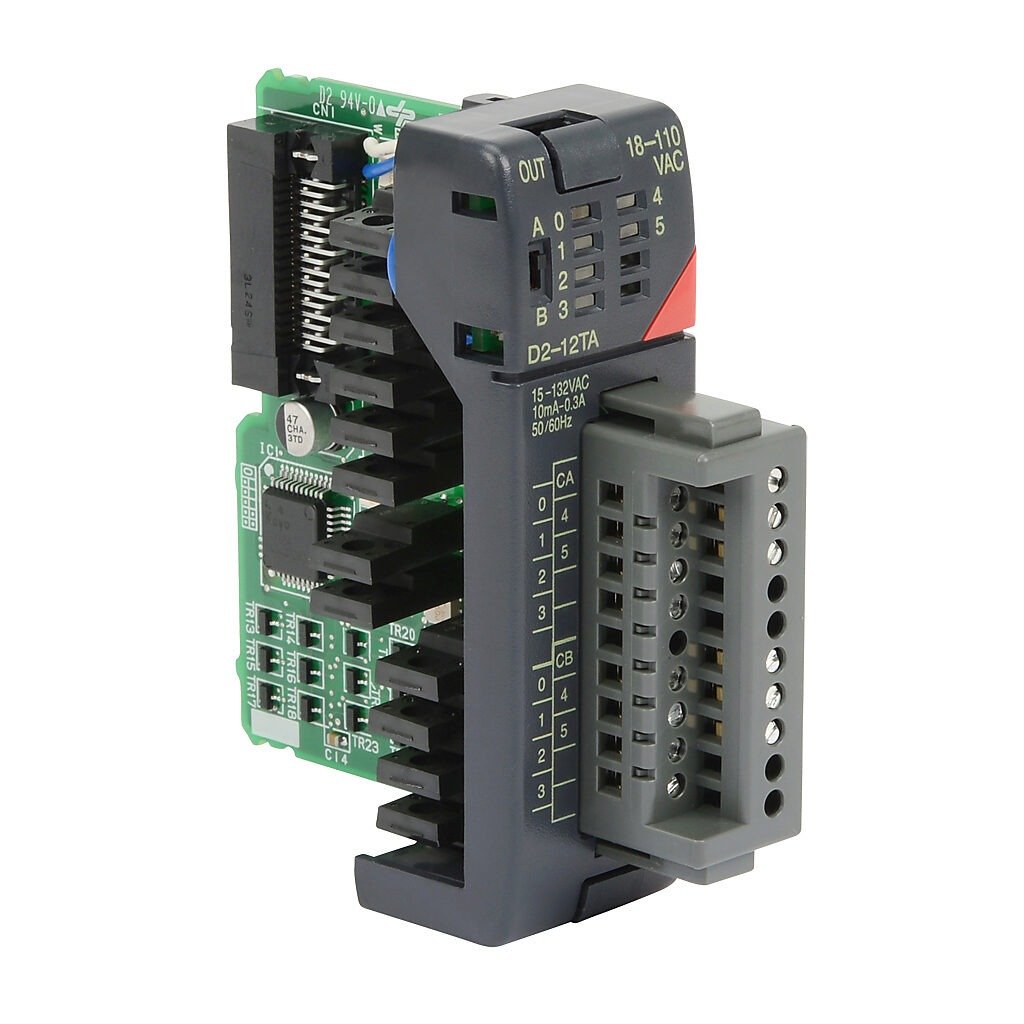

12-Point DC Discrete Output Module for Industrial PLC Systems

In modern industrial automation, precision, reliability, and efficiency are essential. A 12-point DC discrete output module for industrial PLC systems plays a critical role in ensuring accurate signal transmission between programmable logic controllers (PLCs) and field devices. These modules are designed to convert control logic signals from the PLC into electrical outputs that activate relays, solenoids, contactors, indicators, and other industrial equipment.

One widely recognized example in this category is the 140ddo88500, a module commonly used in large-scale automation environments where performance and durability are non-negotiable. Understanding how such modules function and where they are best applied can help engineers and technicians make informed decisions when designing or upgrading control systems.

What Is a 12-Point DC Discrete Output Module?

A 12-point DC discrete output module is an input/output (I/O) component installed within a PLC rack. It provides 12 independent output channels, each capable of sending DC voltage signals to connected field devices. These outputs are typically used to control:

- Motor starters

- Relay coils

- Solenoid valves

- Alarm systems

- Indicator lights

- Industrial actuators

Each channel operates independently, allowing the PLC to control multiple devices simultaneously with high accuracy. The 140ddo88500 is designed to operate within a defined DC voltage range, making it suitable for industrial environments that require stable and consistent output control.

Key Features of a 12-Point DC Output Module

High Channel Density

With 12 output points in a single module, engineers can reduce panel space and simplify wiring layouts. This compact configuration is ideal for control panels where space optimization is important.

DC Voltage Compatibility

DC output modules are commonly designed for voltage ranges such as 24V to 125V DC. This flexibility ensures compatibility with various industrial devices. The 140ddo88500 supports DC operations that align with common industrial standards.

Electrical Isolation

Industrial environments are prone to electrical noise and voltage fluctuations. Output modules typically include built-in isolation between channels and the backplane to protect the PLC processor from electrical damage.

High Current Handling

Each output channel is designed to manage a specified current load. This ensures reliable switching of connected devices without overheating or performance degradation.

How It Works in an Industrial PLC System

Signal Transmission Process

- The PLC processor executes control logic based on program instructions.

- When an output condition is met, the processor sends a signal through the backplane.

- The discrete output module receives the signal.

- The module switches the corresponding DC output channel ON or OFF.

- The connected field device responds accordingly.

For example, if a temperature threshold is exceeded, the PLC may activate a cooling fan through one of the 12 output channels. The 140ddo88500 ensures that this signal is delivered reliably and consistently.

Applications in Industrial Automation

Manufacturing Lines

In automated production systems, discrete output modules control conveyor belts, robotic arms, packaging machines, and sorting systems. Multiple outputs allow synchronized operation across various machines.

Process Industries

Chemical plants, oil refineries, and water treatment facilities rely on precise control of valves and pumps. A 12-point DC output module ensures timely activation and shutdown of these critical components.

Power and Energy Systems

Energy distribution systems use PLC outputs to control breakers, alarms, and monitoring devices. The durability of modules like the 140ddo88500 makes them suitable for high-demand environments.

Building Automation

HVAC systems, lighting controls, and security systems use discrete outputs to manage electrical devices efficiently.

Benefits of Using a 12-Point DC Discrete Output Module

Improved System Efficiency

Centralized control through a PLC reduces manual intervention. Output modules automate switching operations with speed and precision.

Reduced Wiring Complexity

Instead of using multiple relays and manual switches, a single module consolidates output control into a compact, organized solution.

Enhanced Reliability

Industrial-grade modules are built to withstand harsh conditions such as vibration, dust, and temperature variations. The 140ddo88500 is engineered for long operational life in demanding environments.

Easy Maintenance and Replacement

Modular PLC systems allow quick replacement of faulty output cards without dismantling the entire system. This minimizes downtime and production losses.

Installation and Integration Considerations

Rack Compatibility

Before installation, ensure the module is compatible with the PLC rack and backplane system. Proper alignment and secure mounting are essential for stable operation.

Load Requirements

Check the voltage and current specifications of connected devices. Overloading an output channel can damage the module.

Wiring Best Practices

- Use appropriately rated cables.

- Maintain proper grounding.

- Label all connections clearly for troubleshooting.

Correct installation of modules such as the 140ddo88500 enhances performance and prevents operational failures.

Safety and Protection Features

Industrial output modules often include built-in protective mechanisms such as:

- Short-circuit protection

- Overcurrent protection

- Thermal monitoring

- Status indicator LEDs

These features help technicians quickly diagnose issues and ensure safe operation within control panels.

Why Choose a 12-Point Configuration?

A 12-point configuration strikes a balance between capacity and efficiency. It provides sufficient output channels for mid-sized automation systems without consuming excessive rack space. This makes it ideal for:

- Medium to large manufacturing plants

- Infrastructure automation

- Process control systems

Modules like the 140ddo88500 are specifically designed to meet these industrial requirements while maintaining stable and dependable performance.

Future of Discrete Output Modules in Automation

As automation technology advances, discrete output modules continue to evolve. Modern systems emphasize:

- Improved diagnostic capabilities

- Energy-efficient switching

- Enhanced communication integration

- Higher durability standards

Despite the rise of smart devices and network-based controls, discrete output modules remain a fundamental component in PLC architectures.

Conclusion

A 12-point DC discrete output module for industrial PLC systems is a vital element in modern automation. It enables precise control of multiple field devices, enhances operational efficiency, and reduces system complexity. Whether used in manufacturing, energy, or process industries, these modules provide reliable and consistent performance.

The 140ddo88500 stands as a strong example of a robust and dependable solution in this category. By integrating such a module into your PLC system, you ensure efficient signal control, improved reliability, and long-term operational stability in demanding industrial environments.